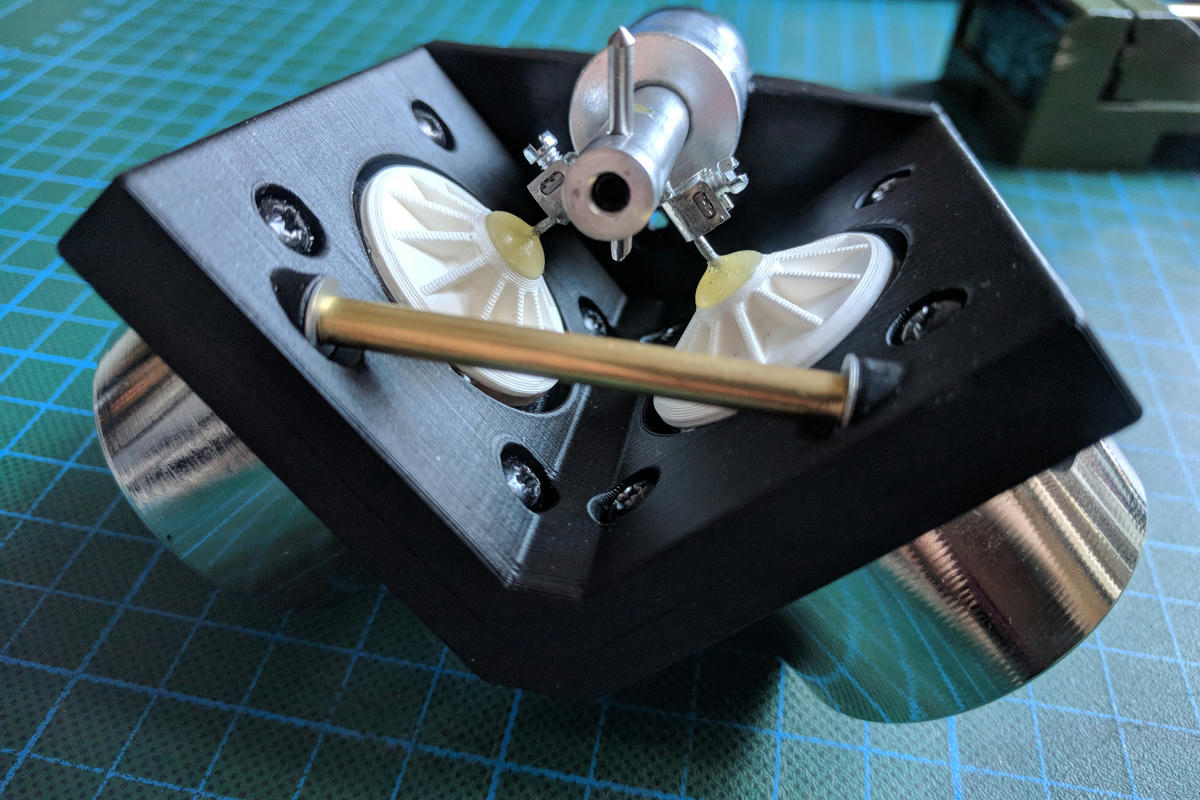

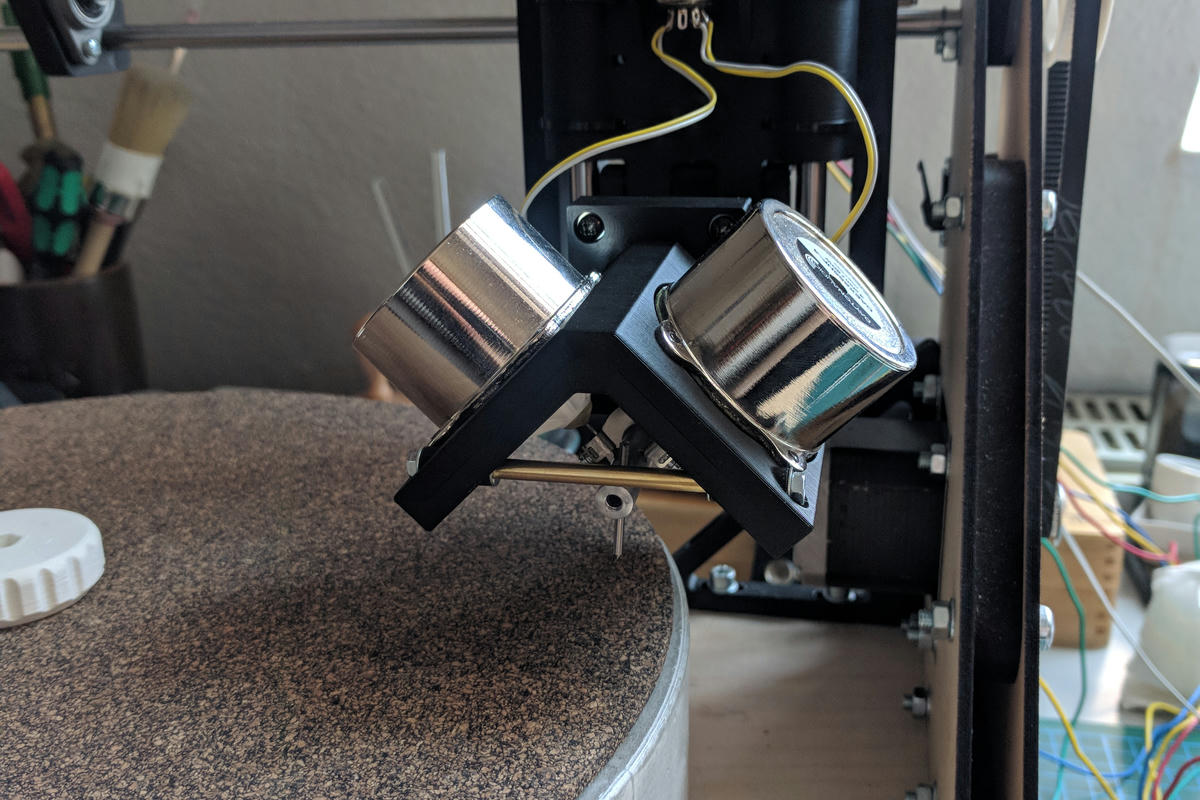

Record Lathe, Pt.1

Filed under: Record Lathe

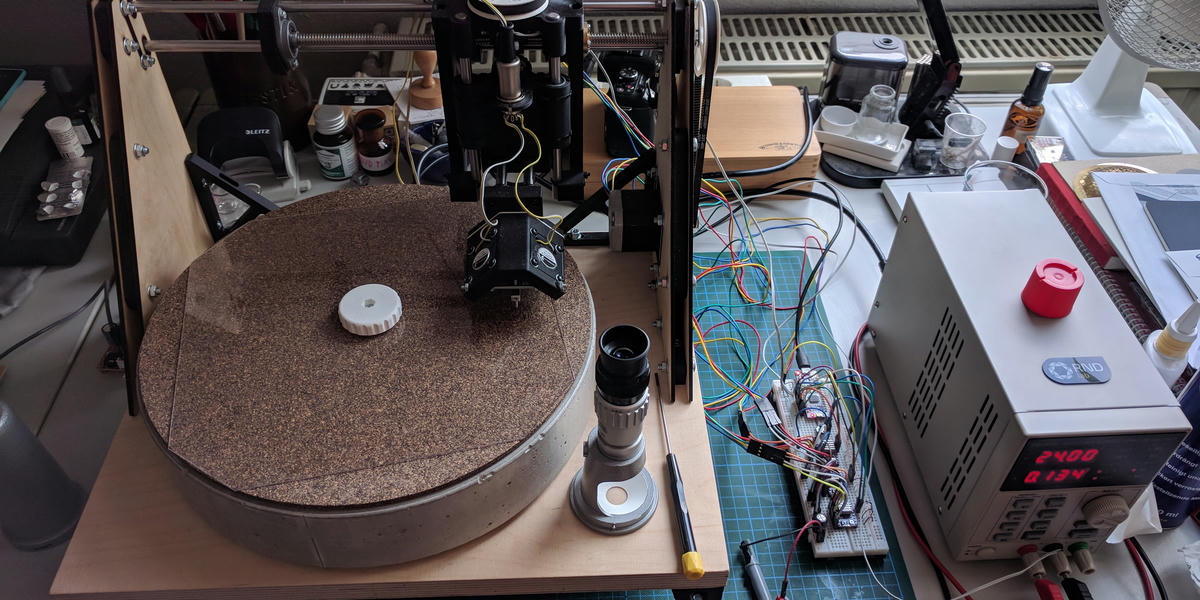

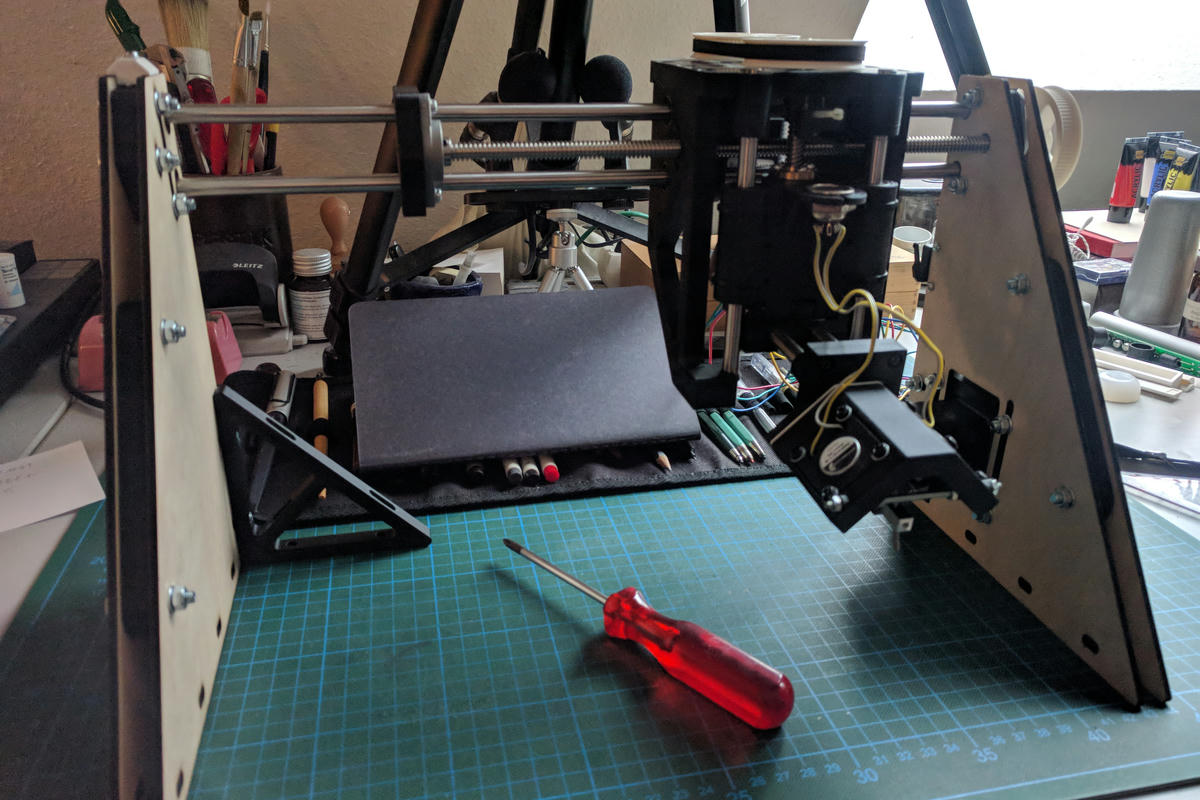

Hi, welcome to the first short introductory post in a series where I’m going to document my attempt at building my own record lathe!

Work on this started around a year ago, but I haven’t really gotten around to documenting any of it outside of some posts on twitter, so I felt it was time to put this project’s documentation into a less ephemeral form.

Wait, what’s a record lathe?!

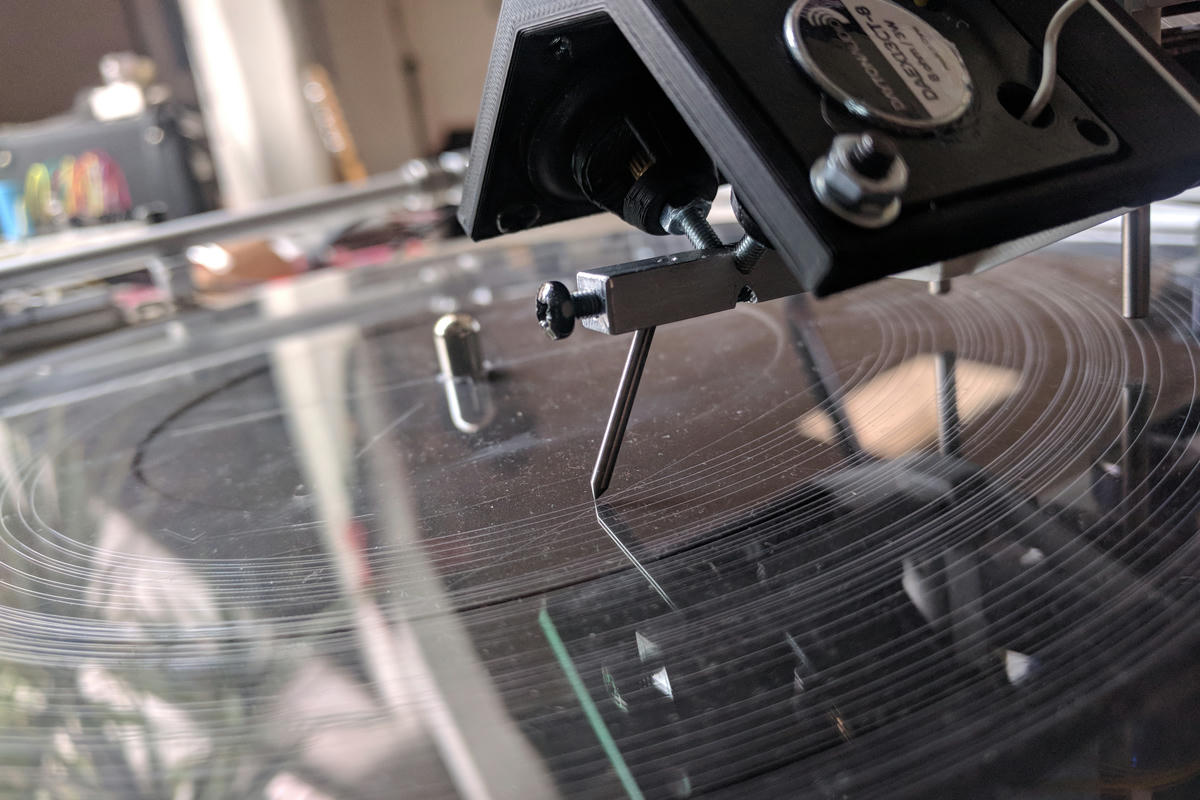

Good question! You know records, right? Round, black, shiny discs that contain music in a spiral groove?